Ever since they came into sight, barcode labels have been widely used. They were first used in retail, but soon enough their usage was expanded to other areas, as well. Nowadays, barcode labels are used in various fields and their purpose is everything but negligible.

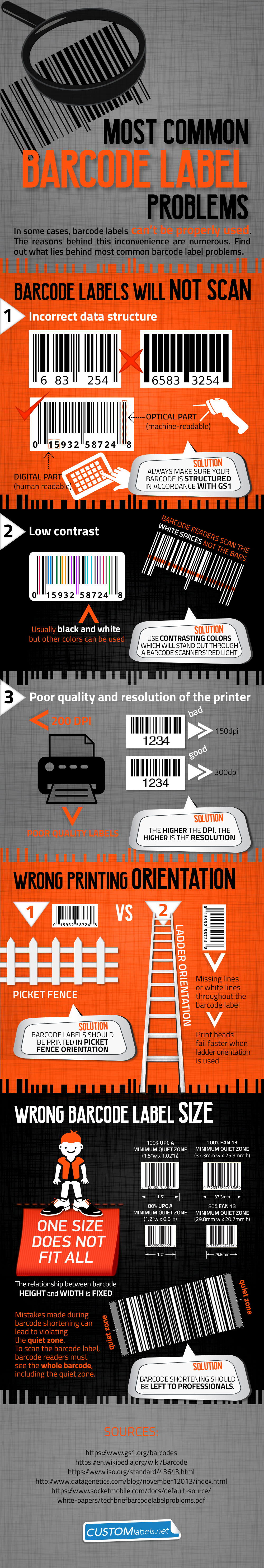

This small, yet powerful, invention is used for reducing data entry errors, inventory tracking and overall efficiency improvement. However, barcode labels can fail to deliver the goods. Sometimes they are unable to be read by barcode scanners, but other times they are just not sticking to the package. Did you ever wonder why is that happening?

Some causes of barcode labels failing are pretty obvious, but others might come as a surprise.

Did you know that direction of printing can affect barcode label scanning? Or that high humidity can cause labels to peel off? The little-known roots of barcode label problems can be tricky to handle, especially in the hands of non-professionals.

Understanding the origin of the problem and using technology properly is a prerequisite for printing barcode labels successfully. When it comes to barcodes, it’s smart to play it safe and consult the professionals.

Taking necessary precautions saves you not only money, but unnecessary troubles, as well. Read about the most common barcode label problems, their causes and appropriate solutions.

Embed this infographic on your website: