Barcodes are one of the most important inventions of the 20th century. The need for this kind of invention became apparent in the 1930s when grocery business began to boom. However, the patent itself wasn’t issued until 1952 when the first, four-lined, barcode system was developed.

Barcodes serve the purpose of transferring product information via specially designed barcode scanners. Prior to introduction of barcoding system, the system of inventory keeping was based on clerks whose job was to list the products manually. Not only did the barcode labels make the job easier and faster, they also reduced the chance for human error.

Though it all began in the grocery industry, nowadays, barcode labels are used in the variety of other fields, and can be found on almost any product or package. As a matter of fact, barcode labels now represent a pervasive element of modern retail industry.

Benefits of barcode labels for business

When it comes to modern technologies in business, no company can afford to fall behind, and using barcode technology provides benefits for business in any industry there is. Though barcodes are sometimes underestimated as a method of saving time and money, they are proven effective. Barcode labels could be essential for taking your business to the next level.

1. Eliminate data entry errors

The most apparent benefit of using barcode labels in your business is eliminating data entry errors. The possibility for making an error for manually entered data is much higher compared to scanning a barcode label.

2. Reduce employee training time

Using a barcode system reduces employee training time, as well. Teaching new employees how to handle an entire inventory or pricing scheme is in the past, since mastering the hand-held barcode scanners takes only a few minutes.

3. Streamline the workflow

Other than being accurate and reliable, barcode labels also streamline the workflow. Tracking down every piece of information, material or product which moves within and outside of the organization can be time-consuming. Barcode labels improve the efficiency by automating this process.

4. Inventory tracking

Barcode labels enable precise inventory tracking. Companies that sell their products using online portals can provide customers with real-time inventory updates. One example would be allowing users to see if the item is available for order or currently out of stock. Tracking equipment’s location during shipping and receiving reduces the time spent on searching for the items and replacing the ones that are presumed to be lost. In other words, by using barcode labels, you can maintain control over inventory, leading to lower overhead.

5. Branding

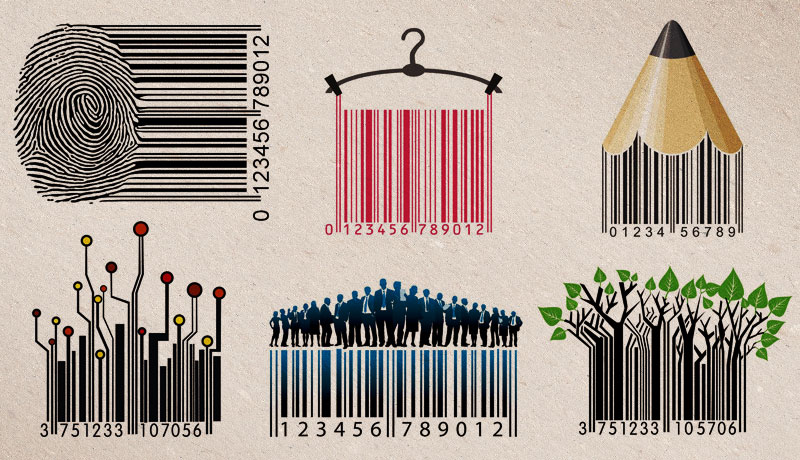

Implementing barcode labels into your business can do wonders for branding, too. It’s no longer necessary to stick to the plain barcode design. Regular black and white stripes can be turned into fully functional piece of art. Designing your barcode label can make your products stand out from the others and, eventually, improve your business.

In order to print barcode labels you have to decide which barcode is the right one for your business.

Types of barcodes

Barcode started out with a simple 1-dimensional design consisting of black and white lines, but has come a long way since then. Today, not only do barcode labels come in many shapes, sizes and label designs, but there are numerous types of barcodes and scanning systems suitable for both warehouse and manufacturing environments.

Two most commonly used 1-D barcode systems are UPC (Universal Product Code) and EAN (International Article Number). Since the UPC-A was developed with little regard to the situation outside the US, the European organization dealing with the system of product identification developed EAN-13. This type of barcode was created to be as compatible as possible with its predecessor, with additional information about the country of manufacturer.

Though UPC-A and EAN-13 are the default barcode versions, both barcode systems have smaller versions (UPC-E and EAN-8) for packages with limited space available, like chewing gums.

Both UPC and EAN are ISO (International Organization for Standardization) and GS1 approved. GS1 is a non-profit organization which maintains global standards for business communication. The organisation is present in more than 100 countries and it’s the official source for assigning company prefixes and creating barcodes in all industries.

Although both barcode systems are widely recognizable, it’s important to mention that some countries have their preferences. Since there are no indications that the US and Canada will switch to the EAN, if you are doing your business within the borders of these two countries, the safer option is to get the UPC barcodes for your products. This is, also, a viable solution because UPCs can be transformed into EANs, but not the other way around. However, if you are selling worldwide, you might consider putting both the UPC, and EAN numbers on your barcode label.

Barcode are inexpensive to design and print. Moreover, barcode labels can be attached to any kind of surface, be it paper, plastic, glass, wood, or metal. Barcodes are extremely adaptable. You can create custom barcodes to best fit your numbering and inventory system and use them for any kind of data collection. However, before you bring printing barcode labels to action, make sure to avoid common barcode label problems.